innovations

standards

Since its establishment in 2004 , UTE (United Technology Establishment) began its journey by supplying general pharmaceutical production lines to local pharmaceutical manufacturing plants. Since then, it has set its sights on gradual expansion toward integrated industrial solutions in the pharmaceutical sector.

In 2025, Optimum Er was launched to serve the Middle East and North Africa region, as the subsidiary trading arm specializing in importing production lines for the pharmaceutical industry, along with medical supplies, raw materials, and packaging materials.

On time

Executing projects on schedule reflects a strong commitment to the timeline, ensuring effectiveness and efficiency in production processes while meeting time-sensitive needs to fulfill customer expectations.

Follow-up

The execution of production lines lies in precise follow-up, as this follow-up enhances the level of supervision and ensures the continuity of operations efficiently. It contributes to achieving outstanding performance and guarantees the successful implementation of projects with high efficiency.

Automation

Automating factories and production lines enhances efficiency and reduces errors by organizing and executing processes automatically, contributing to increased productivity and improved product quality.

The pharmaceutical industries

We partners in Success!

- Solutions for your manufacturing business

- Design, construction, and testing at the highest quality standards

- Achieving the best results at a reasonable cost

- Selecting specialized tools and machines

SOLID DOSAGE

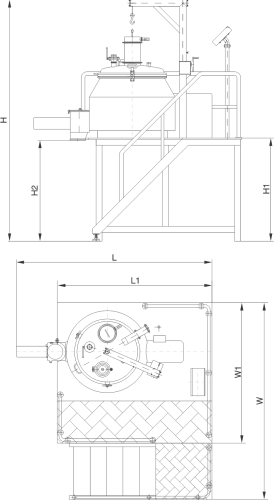

WET TYPE GRANULATOR

The machine is a process machine widely applied for solidpreparation production in the pharmaceutical industry. It has such functions as mixing, granulating, etc. It is widely used in suchindustries as medicine, food, chemical industry, etc.

*Available in various sizes

INJECTIONS

WATER FOR INJECTION (WFI) SYSTEM

WATER DISTILLER SYSTEM

PURE STEAM GENERATOR

Delivery

Post-project follow-up

Production

Implementation of integrated pharmaceutical projects in compliance with international standards

Construction

Supplying pharmaceutical plants with all types of pharmaceutical production lines, including specialized medicines.

Achievement

We offer comprehensive technical solutions and consultations for existing pharmaceutical plants to enhance infrastructure efficiency upgrade production lines in line with latest global pharmaceutical industry standards.

LIQUID LINES

LIQUIDS PREPARATION LINES

Liquid preparation line consist of mixing tanks storage tanks loops micro filters and SS piping system , to meet GMP standard

CLEAN ROOMS

CLEAN ROOMS SYSTEMS

CLEAN ROOMS STRUCTURE

- PANEL WITH ACCESSORIES

- DOORS WITH ACCESSORIES

- WINDOWS FLOORING

- WEIGHING BOOTH

- PASS BOX