SEMI SOLID

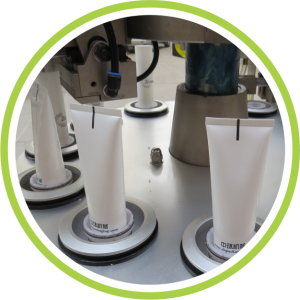

AUTOMATIC & SEMI AUTOMATIC TUBE FILLING MACHINES

The Automatic Tube Filling, Sealing and Coding Machine consist of a main structure, tube moving with a tube holding unit, safety acrylic enclosure (OPTIONAL), jacketed hopper with a stirrer (OPTIONAL), filling nozzles, sealing head, coding unit, hot air sealing unit, electrical panel, PLC & HMI (OPTIONAL), mains on/off & motor.

The best global technologies

- Efficiency at work

- Speed in project delivery

- Experts and mastery at work

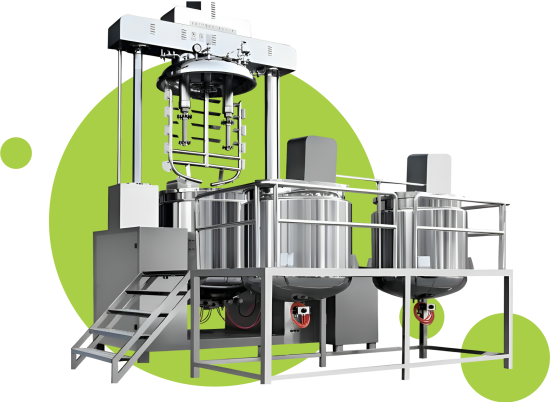

EMULSIFYING MIXER

Emulsifying mixer is the most popular vacuum emulsifier homogenizer is suitable for making small to large batches of cream and emulsions.

SUPPOSITORIES LINES

suppository filling automatic production line has a stable and efficient preheating mold, heated mold, molding, belting, canned, frozen, sealing bolt all production processes such as complete system process, grain production capacity of 8,000-23,000 / hour.